A deep determination to manufacturing top-quality, good quality solutions and superb purchaser fulfillment is our number 1 priority. The metering and dispensing programs that Ivek makes offer exceptional performance and reliability for probably the most demanding apps.

Supplies of design for all factors, particularly all Speak to sections, for example equipment pipe get the job done; internal components of purchased fittings like automated valves together with elastomeric and mechanical seals; pipeline joint seals; welding resources; filters and filter housings like casing and substrate levels of cartridges, and also the most important medium and all elastomeric seals; and polymer extrusion machines.

A crucial assessment from the groupings and their contents showed that we did not have a selected doc centered on the know-how of sterile filling. Although there were paperwork addressing aseptic tactics and sterility assurance controls, there was practically nothing precise into the tools and means of having an item right into a sealed container–closure process. The filling course of action stage has lots of prerequisites to get satisfied, like:

On account of the high pressure extrusion process, the parison reaches a temperature of a hundred and seventy° - 230° C. The configuration and inner integrity with the parison are taken care of by an interior downward circulation of filtered air under pressure.

In the pharmaceutical sector, good quality chance administration is ever more turning out to be a requirement. Numerous, Otherwise all, regulatory companies understand QRM for a component of the standard program that allows the reduction, checking, and managing on the chance and/or affect of threat.

Note: No amount of shell out is regarded as being wages or payment until finally these kinds of total is earned, vested, and determinable. The amount and availability of any bonus, commission, incentive, Advantages, or any other kind of payment and Advantages that are allocable to a specific employee continues to be in the business's sole and complete discretion Except if and right until compensated and may be modified at the corporate’s sole and complete discretion, in keeping with applicable legislation.

Assumes other responsibilities and obligations, as essential, within the Device Dose / Multi Dose Office, in order to present the expected help to make certain adherence towards the output timetable

Extensively acknowledged for its operational efficiency, BFS know-how can fundamentally completely transform output dynamics by integrating these important procedures.

The welder has only one consumable — single-use click here cutting blades. To make certain cleanse and sterile welds, chopping blades are discarded just after use.

A. The most important difference between aseptic processing and terminal sterilization is when the sterilization phase happens in the process. In terminal sterilization, the sterilization is executed following the API, excipients, containers, and stoppers are actually assembled. The assembled merchandise is then subjected to higher warmth and/or radiation that renders the final solution sterile. Terminal sterilization procedures are severe and can have damaging consequences over the efficacy of the solution.

Applicable only to applicants making use of into a posture in almost any spot with shell out disclosure necessities underneath point out or neighborhood legislation:

Main packaging supplies transferred by personalized entry. Dynamic move check here box is just not in function.

Aseptic processing or manufacturing refers to treatments and pursuits for preparing drug formulations, filling them into applicable containers for example vials, and finally packaging the products and solutions though making sure the product and generation atmosphere keep on being sterile and contamination free of charge.

This consistency makes certain that pharmaceutical products and solutions retain their supposed dosing and formulation, reducing the chance of variants that can effect individual outcomes.

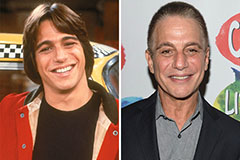

Tony Danza Then & Now!

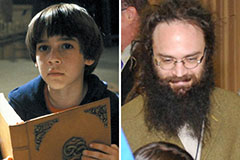

Tony Danza Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now!